Forming the Future

Since 2010...

About UsJoining the forces with the best

Partnership between Opsan, Turkey’s most important automotive parts and components manufacturer and Linde+Wiemann, offering solutions to world brands with more than 60 years of experience…

We are among the world’s most reliable automotive industry manufacturers with roll forming lines, welding stations, product-specific production lines and ISO 14001:2015, ISO 9001:2015, IATF 16949:2016 quality certificates.

Products and ServicesInternational Quality from Design to Production

We offer customisable solutions ranging from mould design and production to product delivery with…

Reliable, functional, aesthetic parts and components supported by advances in material science and lightweighting…

Innovative possibilities offered by the developing technology, our R&D studies and engineering experience.

Employee

0

+

Indoor facility area

0

K m²

Continuously renewed high capacity

Advanced Technologies, always aiming to offer highest quality products, responding to customer needs with the highest capacity and speed…

We continuously develop our technologies in line with current requirements and support our production capacity and speed with innovative approaches to fully meet the needs of our customers.

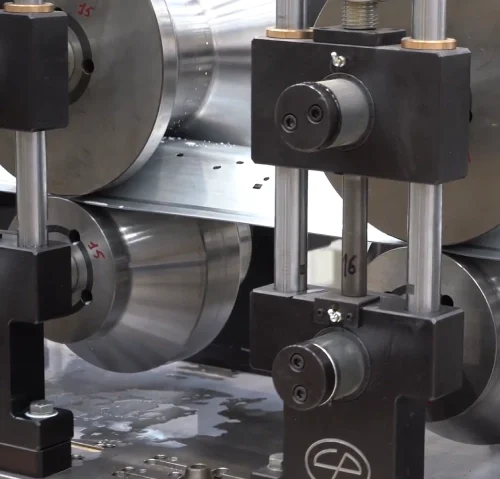

With 129 robots, 5 roll forming lines, 5 stretch bend units, 5 stretch bend units, 13 AF unit projection resistance welding machines, we weld 130 million spot welds and 55 million fasteners and process 20 thousand tons of UHS materials annually in our two separate facilities with a total closed area of 25 thousand square meters.

Production TechnologiesInnovative technologies, innovative products

Roll form

stations

stations

0

+

R&DR&D and Engineering Works

01

Brand and Mold Design

Design and production of roll form reels and moulds used in pre and post punching operations, required for specific projects....

02

Smart Roll Form Stations

Smart roll forming stations and cassettes equipped with innovative sensing technologies for use in profile production with high-strength materials...

03

Flexible Roll Forming

Economical and fast production with high strength materials thanks to moving roller systems that can perform 3-axis bending in variable cassette roll form parts...

04

Reconfigurable Mobile Tandem Press Lines

Cutting and punching operations with high position accuracy prior to the roll forming process, minimum set-up time, scalable energy utilisation....

05

High Volume 3D Scanning Systems

Measurement of parts up to 3 metres in diameter and up to 1500 kilograms with high resolution cameras at maximum speed and precision and reverse engineering possibilities...

06

Robotic Welding Seam Control

Performing dimensional, detailed asset and welding quality controls of the products designed in line with customer needs...

07

Roll Form Section and Sheet Metal Control Systems

Control of surface tolerances of manufactured parts, in-line scanning with high precision laser sensors.

To make the future liveable...

WE MAKE THE PRINCIPLE OF SUSTAINABILITY ONE OF THE CORNERSTONES OF OUR CORPORATE CULTURE.

We establish sustainable relationships with our customers, teammates, our industry, society, the environment, all living things, in short, with all components of the ecosystem. Our main goal is to transform the impact we create as a result of our activities into value and to grow positively in all areas of life.

We establish sustainable relationships with our customers, teammates, our industry, society, the environment, all living things, in short, with all components of the ecosystem. Our main goal is to transform the impact we create as a result of our activities into value and to grow positively in all areas of life.

WE CARE ABOUT OUR EMPLOYEES AND THEIR DEVELOPMENT.

We support our teammates in areas such as career development, work-life balance, working environment, social activities, and equality, and continuously improve the creative and motivating working environment we have generate in order to offer them the best working experience.

We support our teammates in areas such as career development, work-life balance, working environment, social activities, and equality, and continuously improve the creative and motivating working environment we have generate in order to offer them the best working experience.

WE SEE ENVIRONMENTALLY FRIENDLY PRACTICES THAT WILL SET AN EXAMPLE FOR SOCIETY AS AN INTEGRAL PART OF OUR SOCIAL RESPONSIBILITY.

In our procurement, production, and logistics processes, we pay attention to issues such as the use of environmentally friendly methods, minimising waste, increasing energy efficiency and protecting water resources.

In our procurement, production, and logistics processes, we pay attention to issues such as the use of environmentally friendly methods, minimising waste, increasing energy efficiency and protecting water resources.

Our Co-operationsTogether, we are much stronger.