The ultimate point reached in high quality bending processes...

With our advanced stretch-bend technology, we ensure sustainability, quality and safety in every part we produce.

Our stretch-bend lines allow components such as roof rails, window frames and bumper beams to be formed with precision and surface quality that cannot be achieved with traditional press processes.

Stretch-bend’s efficiency saves material by largely eliminating the need for post-forming finishing processes, saving time, reducing costs and providing a modern production alternative that promotes sustainability.

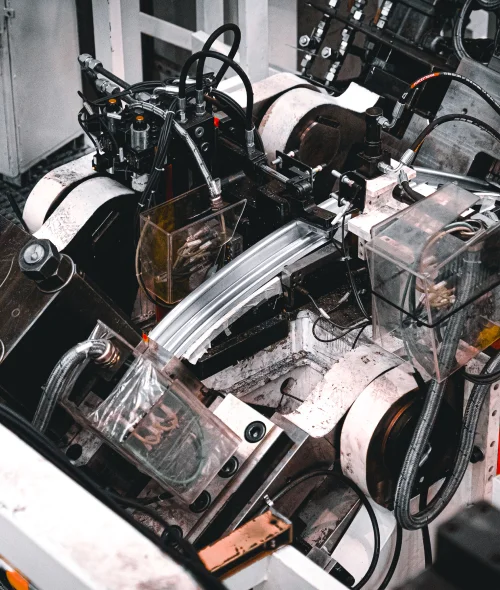

Precision forming at high strength

We utilize high capacity stretch-bend technology to turn challenging designs into products.

In our stretch-bend lines, we shape Ultra High Strength (UHS) materials with strength levels up to 1500 Mpa, including Dual Phase and Martensitic, with precision processes and meet all your requirements with our post-line punching options.

- 2D & 3D bending capability

- 20 tons bending force

- 100 tons tension force

- 12 axis CNC machining

From design to production...

Innovative solutions are the source of trust

We support our control system, which we apply meticulously in all steps from concept to production, with our expertise in design and project implementation.

We transform all our projects into products using simulation-based process design from the design stage, aiming to achieve the highest efficiency at every stage.

Our competencies in in-house mold design and production enable us to offer fast and effective solutions to special needs, ensuring that projects are completed on time and at the most cost-effective cost.

- In-house mold design and production

- Simulation-based process design

- Project management from design to productionTasarımdan üretime proje yönetimi